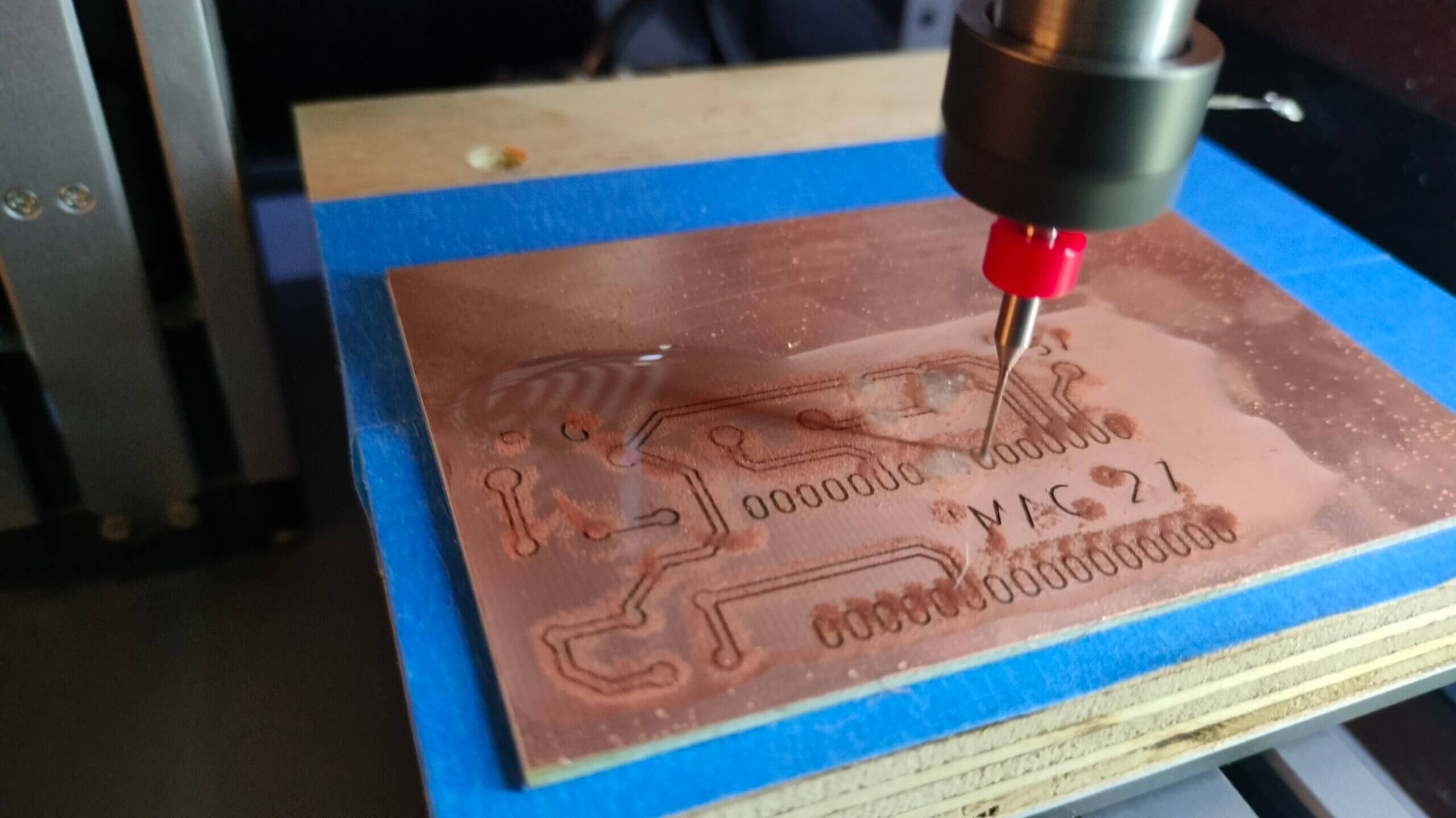

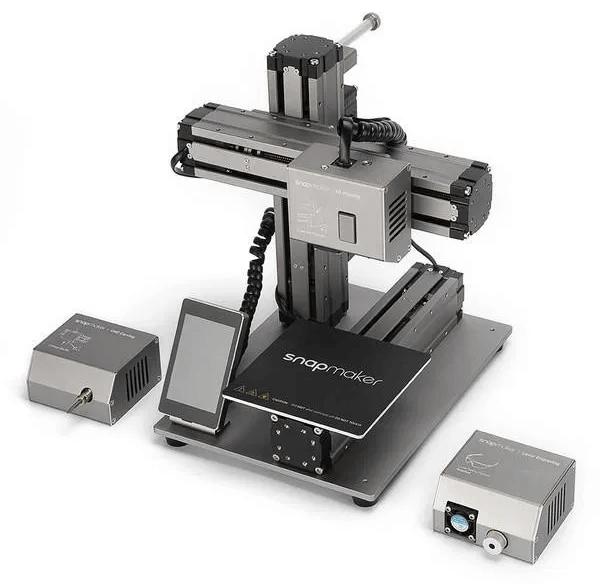

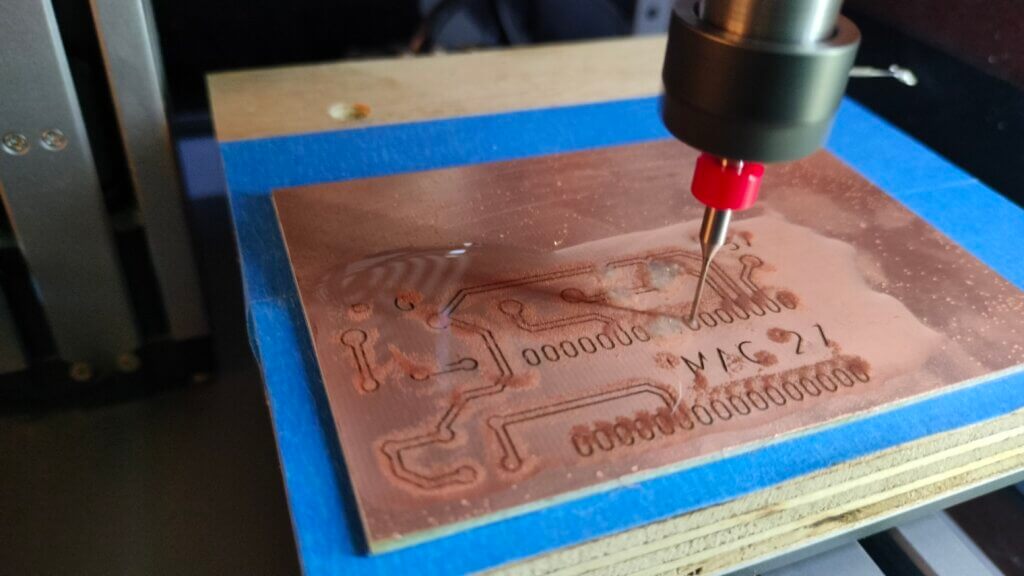

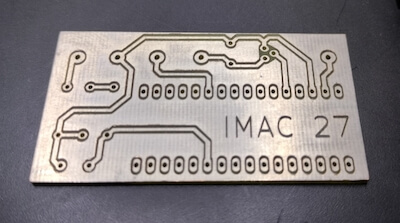

As the owner of a Snapmaker Original v1 3-in-1 3D printer (3D printing, machining and laser engraving), I had to design a machining head worthy of the name. The original machining module was far too weak in terms of power to be able to properly machine wood, plastic or, as I wanted to do, PCBs for my electronic assemblies.

Snapmaker Original v1 features

- All aluminum

- Printing volume 125x125x125 mm

- 200 mW laser (1600 mW extension module)

- Machining at 19,000 rpm

- Touch control

- Z extension: 221 mm

- Box (for ABS printing)

Total cost new (with options): +1,500 € when released in 2020.

Purchased used: €400 in 2023.

Flaws: proprietary software, Snapmaker no longer produces this model since the release of v2 in 2022, and no spare parts or updates are available. Print volume too low, but ideal for producing small parts (mechanics, electronics, DIY, model-making…) For a printer originally priced at over €1,000, it’s a bit of a shame!

3D printing has come on leaps and bounds in just a few years, and for the price spent in 2020 you now have far more powerful machines like the extraordinary Bambu Lab X1.

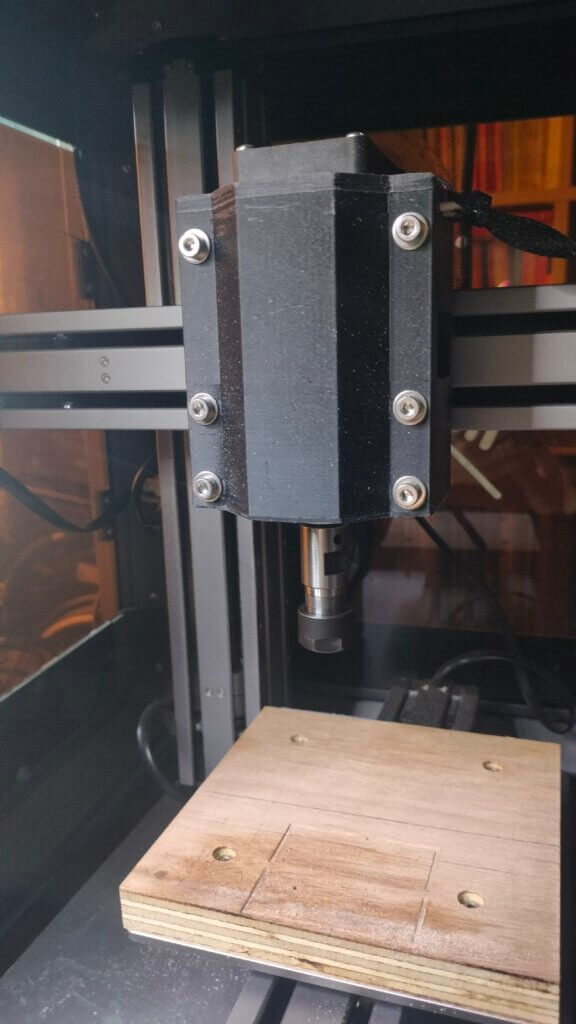

The original head motor burned out after a few tries. The (Chinese) motor inside is nowhere to be found on the net. The circular stator guide broke. So I decided to create my own machining head.

Features

- Power 300 W

- Voltage 12 V

- Variable spindle speed from 7,500 to 20,000 rpm

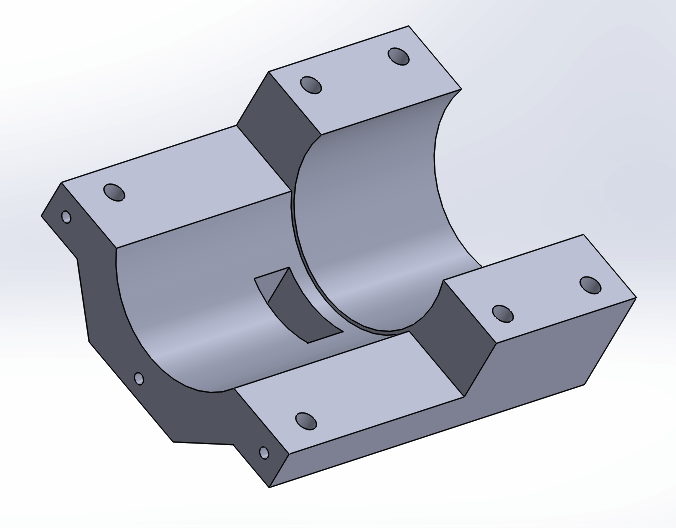

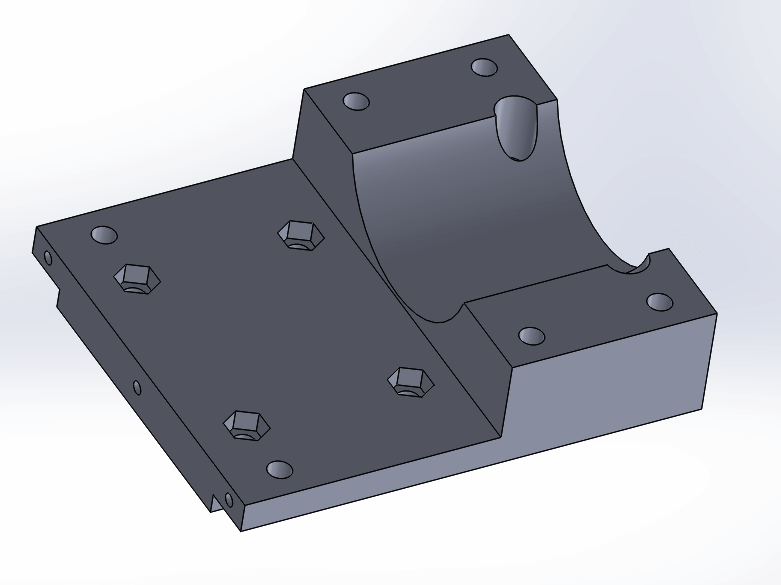

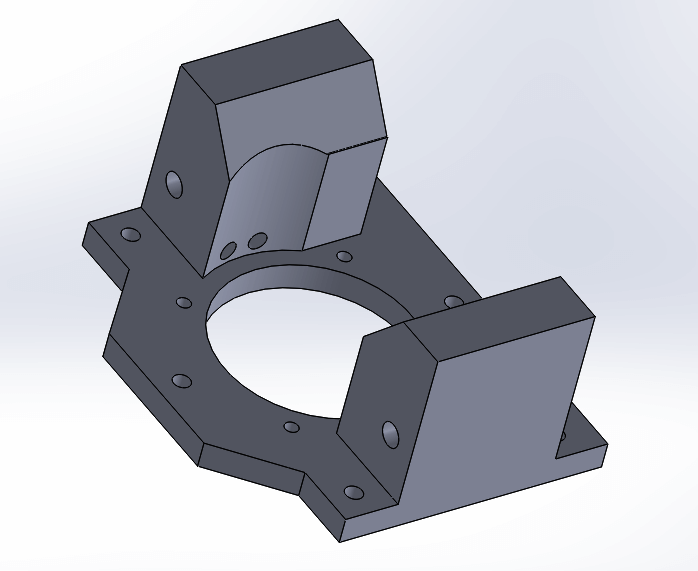

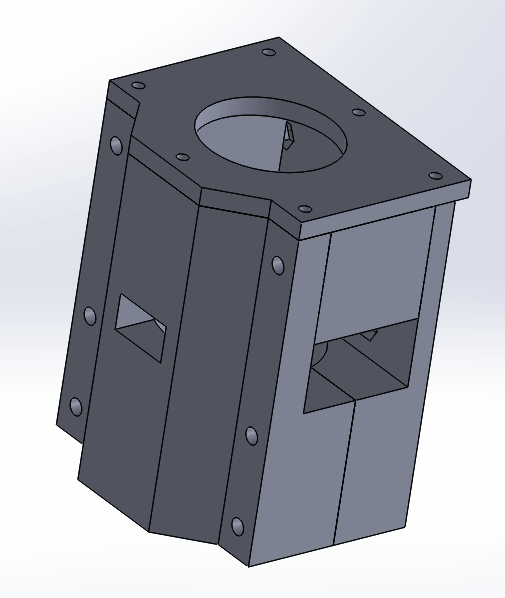

Design

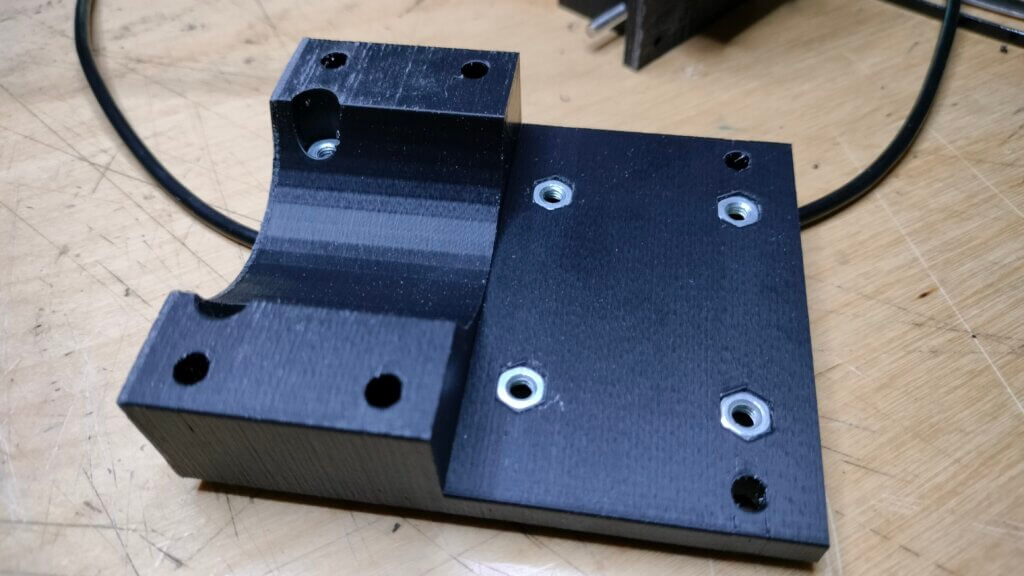

The various parts were designed in Solidworks and then exported in STL for 3D printing.

Printed in ABS for its mechanical characteristics, the components have been assembled with the motor and a small fan on top to aid cooling.

Power supply box

The power supply unit controls the speed of the machining motor. It includes a switched-mode power supply and a regulation module. All components are available on Amazon.

Components :

- 1 MEAN WELL LRS-350-24 switch-mode power supply unit

- 1 type 775 DC 12 V high-torque motor, max. 20,000 rpm, with double ball bearings

- 1 Aideepen PWM speed controller for DC motor (DC 6-60 V, 12 V, 24 V, 36 V, 48 V) 30 A

- 1 5 mm collet chuck for 3.175 mm end mills

- 1 plastic case 180 x 260 x 65 mm

- 2 red/black male banana plugs

- 2 banana plugs, female, red/black chassis

- 1 male RCA plug (fan power supply)

- 1 female RCA chassis plug

- 1 fuse holder with 10A fuse

- 1 round switch

- 1 CE 230V chassis socket

A short video showing what you can now do with this 3D printer

For your CNC milling cutters, the excellent CNC Fraises website and its owner Christophe will be able to advise you.